Below is a condensed version of the case study, and if you want to read the expanded version, you can find the full case study by clicking on the link below.

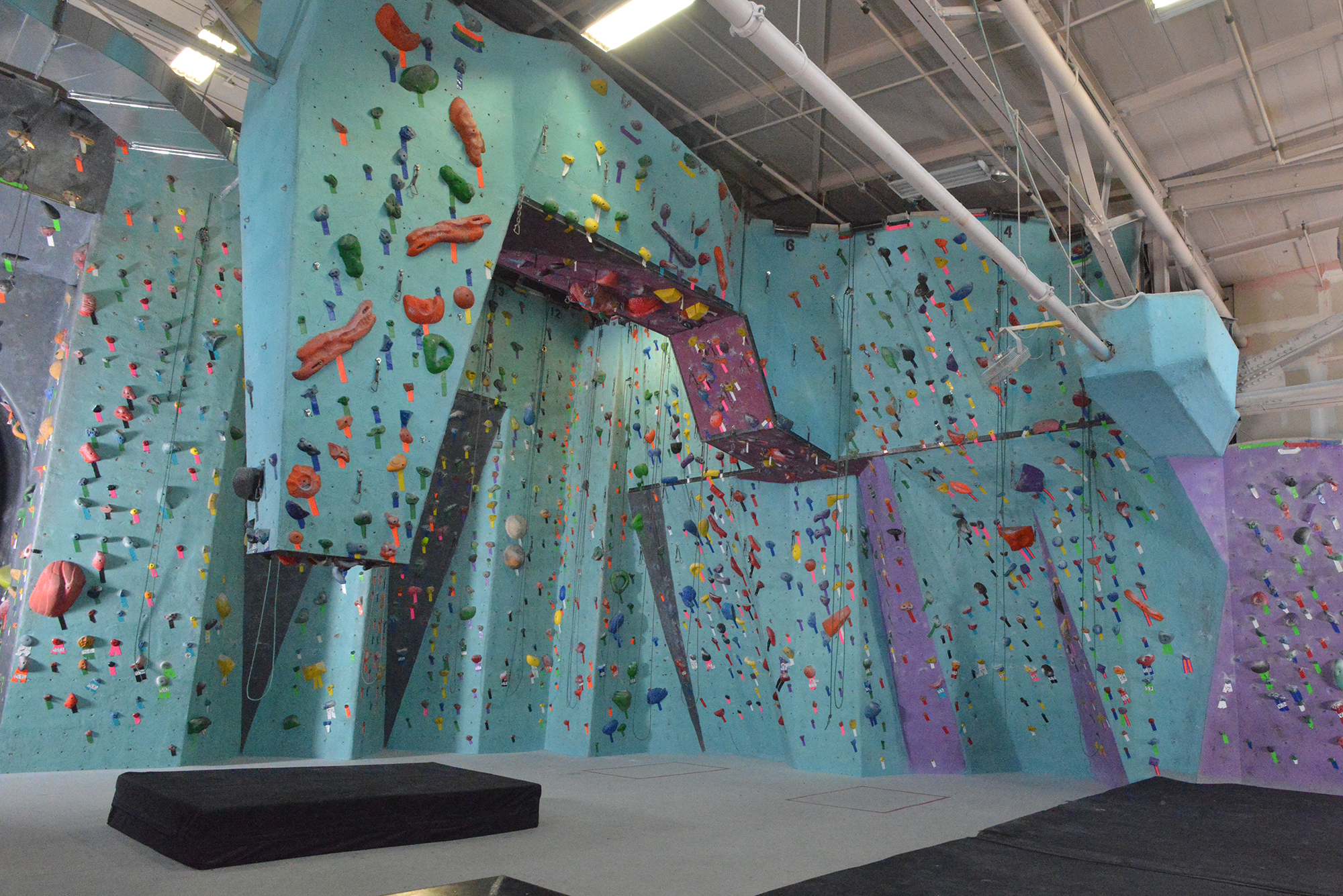

Case Study: Brooklyn Boulders Renovations

Full image set of the BKB renovation project found in the web-gallery here.

Brooklyn Boulders, one of the nation’s leading indoor climbing facilities, planted their roots in the Gowanus neighborhood of Brooklyn back in 2009. With a massive plan to rock the climbing world, they set out with a fantastic space, a vision, and their own grassroots construction methods and materials. What they didn’t know right away, was how quickly their brand would expand to facilities in Chicago, Boston and into the next borough north, Queens.

Seven years after their initial opening in Brooklyn, they had four stunning facilities on their hands, and one major problem: their owner-built walls at the Gowanus location were tired and out-of-date. They served their purpose for many years but they no longer aligned with the BKB image of top-tier quality climbing, unique experiences focused on outdoor enthusiasts, and seamless branding from one facility to the next. Additional complexities were introduced due to more than expected maintenance as a consequence of age and construction method. So the BKB team once again pushed for a new step forward: Major reconstruction on a significant percentage of their climbing walls.

Brooklyn Boulders could choose any climbing wall builder in the market, despite their previous experience using Vertical Solutions. However, as defined by the problem, they could not seek any alternative options that:

More found in the Brooklyn Boulders Renovations Case Study

Vertical Solutions was selected as the only company that could meet or exceed all of the identified objectives. The design team only had 3 weeks to design and fully engineer 5000 square feet of rope climbing walls; a task usually coming in over twice the allocated timeframe (7 weeks typically). In order to accomplish this, considerations for the wall design style had to be made to match the project. Vertical Solutions relied on their extremely agile, accurate, and adaptable construction method of choice: The new MLM wall construction process utilizing wood CNC machine production panels. This method, which expedites pre-fabrication at HQ in Salt Lake City, delivers a product guaranteed to fit onsite with minimal re-work.

Examples in slideshow above, full image set found in the web-gallery here.

Vertical Solutions delivered all of the following:

This proof of concept executed on behalf of Brooklyn Boulders, illustrates that when a climbing facility needs any of those deliverables, or even all of them at once, Vertical Solutions has the team, expertise, tools and ambition necessary to meet them.

Lance Pinn, President, Brooklyn Boulders

“As usual, we put some very tight and non-negotiable constraints on the project scope that we gave to Vertical Solutions. Additionally, this recent renovation project was by far the most accelerated we’ve ever proposed. The fact that all of this came together and was installed over the holidays without closing our facility was nothing short of monumental. This is New York; nothing closes!

I don’t want to overlook the importance of this project’s design either. We’d built a brand that requires cohesion amongst all the facilities and we couldn’t accept anything that wasn’t spectacular and immediately impressive, yet tailored to the Brooklyn audience. The design team worked with us quickly to get us something fresh and new, with durability being a major priority.

We can’t imagine choosing any other wall builder to get this done right and on-time.”